By Jim Lewis, CEO Enhanced Retail Options LLC

I just lately had the honor of lecturing at my alma mater, the University of Florida. We talked about the basic principles of retail analytics, the resources and roles of retail and wholesale stock planners. We talked about how merchandise conclusions are designed to with any luck , make magic on the revenue flooring. But the magic doesn’t normally occur.

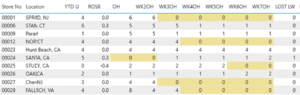

A student questioned what results in a retailer to have vacant shelves. That’s a whole lecture inside of alone. We talked about some of the explanations- what can be managed and what can not. They know what they study- that the pandemic prompted havoc on the provide chain. Though that is genuine, there are many other results in, primarily now that the provide chain is easing. We focused on researching the mechanics of how out of stocks outcome in misplaced product sales. Just one of the experiences I confirmed the stock of an merchandise by shop by week, highlighting when it was out of inventory. Students quickly did the math to determine out how much income was currently being still left on the table.

Track inventory by sku by 7 days by store to uncover outs and shed opportunity.

Predicting Out of Stocks

When there are some merchants whose philosophy is that they’d somewhat be out of inventory than mark down an merchandise, the extensive the greater part do not want to be out of inventory. Protecting against stock outs involves a large amount of relocating areas to sync harmoniously. There ought to be a constant movement of inventory coming from the wholesale aspect with peaks and lulls taken into thing to consider. The allocation process relies upon incredibly considerably on the sophistication of the retailer. Some auto replenishment devices just stick to a least quantity, some increase price of sale to that, but most aren’t clever enough to prioritize merchants and products that are out the most. And many never increase again missing revenue, which means the overall foundation for the forecast does not replicate the genuine opportunity. Then there is the sheer volume of sku’s- tens of millions of sku-keep combos to control.

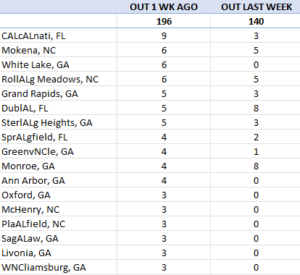

Hold observe of the suppliers or merchandise that are persistently out of stock.

VMI

The ideal approach for keeping in inventory is VMI (Seller Managed Inventory) exactly where the retailer employ’s their supplier’s means to forecast and be certain retailers stay in stock. It mainly usually means people sku’s will have a lot more concentration on them than non-seller managed items. This concentration allows the supplier laser focus on merchants and sku’s that are most probably to go out of stock, and beef them up.

Eventualities

Even with the best of intentions, there might not be adequate stock or open to get to allocate in the most effective method. That’s why documenting scenarios is important. If you only have so several sources- which merchants or goods will get fed very first? What gets prioritized? Or does each shop get a scaled-down volume? These may possibly modify depending on the condition, but we advocate producing a “play book” so there is a prepare in position.

Information Science

It truly is not mind science. We have an abundance of reviews and techniques that frequently study which products and retailers are sold out- so that stock can be prioritized to fix the problem. Based on a combination of details points- wholesale stock circulation, historic keep and product stock outs, seasonality, promotions, etc., we use a number of very simple algorithms to do the operate. It does need powerful computing electric power to sift by means of hundreds of thousands or billions of records of data, so it is not for the faint at heart.

I usually appreciate speaking to college students. At its coronary heart, ERS was founded on education and learning- teaching manufacturers to think and act like shops. It has developed into a lot more over the last 20 several years, but training remains a main aim of our small business.

For additional details, get hold of us.

More Stories

Private Online Shopping – Hawkins ‘Dumped’ From Fashion Extravaganza

The Importance of AutoCAD Knowledge in 2016 and Beyond

BroCal Style: The Rise of Metal Mulisha and the Rest of the Gang